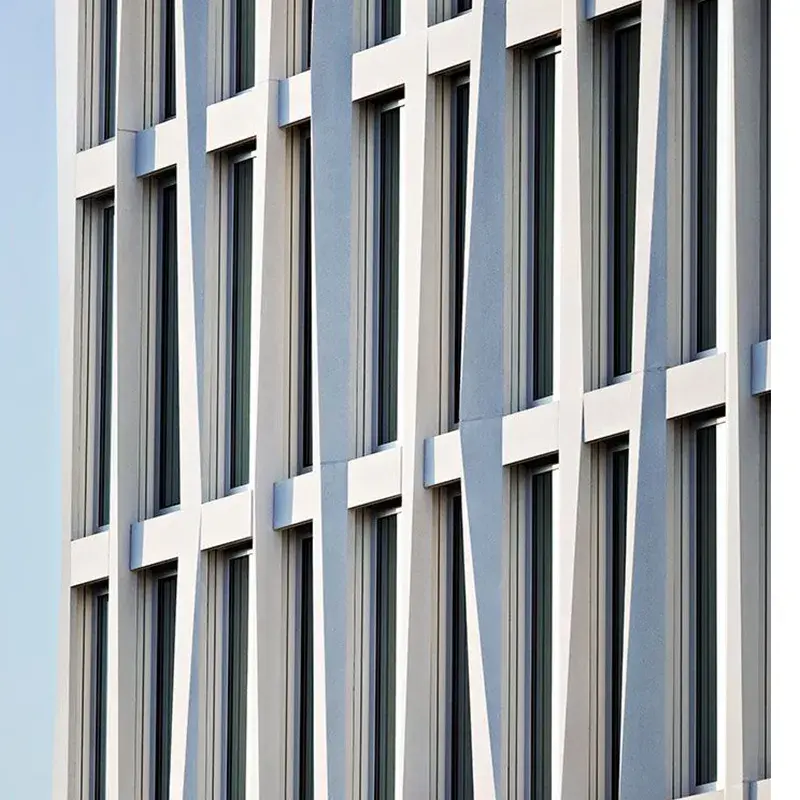

GRC Fins are used as essential parts of multi -storey buildings for their high decorative value and good acoustic properties. Convenient to install, these fins are preferred by civil engineering professionals and architects for their low installation charge, high durability, Eco friendly quality and long lasting surface quality. Impact proof design, steel reinforcement free installation method, capacity to reduce structural load, ability to insulate even low frequency noise and reasonable price are the distinctive attributes of these GRC products. We would like to introduce ourselves as a quality conscious supplier and manufacturer of Glass Reinforced Concrete Fins. We offer the latest and wide range of GRC design panels & FINS to our customers. These high quality GRC Fins & Panels by GRC Bangalore can be given with innumerable textures & finishes and they can be coloured for a better or a theme like look.

GFRC fins are composed of a mixture of Portland cement, fine aggregates (such as sand), water, and glass fibers. The addition of glass fibers significantly enhances the structural properties of the concrete.

Production Process: The production of GFRC fins involves a specialized casting process. The steps typically include:

Mixing: The cement, fine aggregates, and water are mixed together to create a cementitious paste. Admixtures might be added to improve workability and reduce water content.

Incorporating Glass Fibers: Glass fibers, which are thin, flexible strands of glass, are added to the mix. These fibers provide reinforcement to the concrete, preventing cracking and increasing tensile strength.

Casting: The GFRC mixture is cast into molds that are shaped to create the desired fin design. The molds are often made of rubber or other flexible materials to allow for intricate shapes.

Compaction: After casting, the mixture is compacted using vibration or other methods to remove air voids and ensure uniform distribution of materials.

Curing: The cast GFRC fins are cured under controlled conditions to promote proper hydration of the cement and to achieve the desired strength and durability.

Finishing: Once the curing process is complete, the fins can be removed from the molds and further refined through sanding, polishing, or other finishing techniques to achieve the desired surface texture and appearance.

Features and Applications: GFRC fins offer several benefits and are used for various architectural applications:

Aesthetics: Fins can enhance the visual appeal of buildings by adding texture, depth, and dimension to their exteriors. They come in various shapes, sizes, and surface finishes to complement different architectural styles.

Sunshading: Fins can be strategically placed to provide sun shading and glare reduction for building interiors. By controlling the amount of sunlight that enters a space, they contribute to energy efficiency and occupant comfort.

Wind Mitigation: Fins can also be designed to reduce wind loads on buildings, acting as aerodynamic elements that improve the structural stability of the structure.

Privacy and Visual Screening: Fins can be used to create privacy screens or to partially obscure views while maintaining an open and airy feel.

Versatility: The use of GFRC allows for the creation of intricate and lightweight designs that may be difficult to achieve with traditional concrete.

In summary, glass fiber reinforced concrete fins are architectural elements that combine the strength of concrete with the flexibility and reinforcement of glass fibers. They serve both functional and aesthetic purposes in building design, offering benefits such as sun shading, wind mitigation, privacy, and enhanced visual appeal.